Defining Lean Manufacturing

Lean Manufacturing is a term that has been around now for many years, originally spawned within the MIT study that led to the book “The Machine That Changed the World” by Womack and Jones in 1990. However if you search through the many publications and web sites looking for a lean manufacturing definition you will find a myriad of differing definitions for Lean, partly because lean is a continuously developing philosophy and because it’s application is different for each and every company.

Lean has had a number of names over the years, developed primarily from the Toyota Production System (TPS) it has been called World Class Manufacturing (WCM), Continuous Flow Manufacturing, and Stock-less production to name a few. Today you will even here Lean Sigma and Agile Manufacturing.

Although developed mainly within manufacturing, Lean is equally applicable within your office based administrative functions or within service industries such as healthcare where it is seeing a huge amount of attention.

The term Lean in my mind is an unfortunate one, in many people it brings to mind not a fit capable organization but a thin, anorexic one that will break when pressure is applied. A fear that has been well founded when piecemeal and ill planned applications of Lean have failed.

Lean Development

The history of Lean Manufacturing goes back many centuries, well before Ford’s famous production lines for the model T ford; however it really starts to begin to be the philosophy that we know today with Toyota and the development of the Toyota Production System (TPS).

Toyota set out to be far better than Ford and the rest of the US Automobile Industry, an ambition that they quickly achieved despite a lack of resources and infrastructure. They achieved this through the application of Lean Principles and the many Lean Manufacturing Tools.

Toyota are far from perfect by their own admission, they are only part way on their never ending journey of Lean Manufacturing.

What is Lean For?

To understand what lean is it is helpful to understand why it developed; if you can understand the purpose of lean then you can better grasp exactly what it is. Lean (and the Toyota Production System) have two main purposes;

- Provide Customer Satisfaction

- Do so Profitably

Everything within Lean focuses on these two main points, with customer satisfaction taking the fore at all times.

Everything that you do should provide value to the customer, anything else is waste. If the customer does not explicitly want it why are you doing it? This is why when you look at any process your first question should always be “WHY?” Too many practitioners of lean jump straight into applying principles to a process without even questioning why the process exists; often they make a wasteful process more efficient and you end up getting better at doing something the customer does not even want.

Providing Customer Satisfaction

Understanding what your customer really wants is not always as clear cut as it could be. It is also not always clear exactly who your customer is; after all you have to consider your business owners and society as a whole as your customers also. All of your customers want something from you and sometimes those needs are conflicting; society wants you to use less energy but the consumer wants bigger and faster for example.

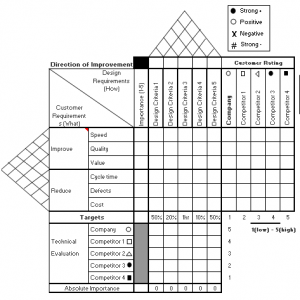

We can use tools such as QFD or Quality Funtion Deployment to try to discover what our customers really value and to also try to weight those values as to what is most important.

QCD (Quality, Cost and Delivery)

Your customer satisfaction however comes down to just three main areas, normally Quality, Cost and Delivery (QCD). However which is the most important to your customer may depend on the product or service that you are delivering. Someone looking for a new sound system may put Quality first, while the consumer that needs a new Sofa may want it tomorrow rather than having to wait 5 weeks. Of course the person looking for a “consumable” rewritable DVD for their computer may only be motivated by the cost.

Understanding your customers needs is vital in being able to keep them fully satisfied and everything you do in the way of services that provide and products should be geared to meeting those needs. This means giving them the best quality, the right delivery time (which is not always immediate) and the right price.

Lean is very much about providing Quality; tools such as Poka Yoke and Kaizen are very much focused on ensuring that service and product quality are perfect.

Lean is also about Delivery; Just in Time is about providing flow using kanban systems to ensure that the customer gets what they want when they want it. We use standardized working through 5S and keep our machines reliable through TPM to help achieve this.

Lean is also about Cost; we reduce our costs by removing all non-value adding steps – but this is the result of implementing lean not the focus of lean. Lean is not “Just” a cost cutting machine to help improve profits without any thought of the customer!

Lean Makes us Profitable

A Business exists primarily to make money, if it does not make money it cannot pay wages, overheads etc and will eventually fail. Even Charities exist to make money for their cause. The more efficiently that a company can do this the happier all involved will be; the employees because their lives are easier and hopefully their wages fair, the customers because the prices are fair and the products good, the suppliers because they are receiving a fair price and finally the owners because they are making a profit.

By employing lean we remove all of the wasteful processes and focus only on providing the customer value; anything that does not provide the customer value is removed or minimized.

A traditional view of profit is one where we base our selling price on our costs plus our profit;

Selling Price = Profit + Costs

However as Taicii Ohno one of the main architects of the Toyota Production system argues; if the customer perceives our product or service to have a specific value they will only pay accordingly. If we raise our prices because our costs increase but the perceived value of our product remains the same our customers will stop buying as our selling price exceeds the value that they perceive.

So Taichii Ohno and Toyota look at profit and costs in the following way;

Profit = Selling Price – Costs

The selling price is the price that is fixed by what the consumer is willing to pay for the perceived value of the product, your profit therefore will depend on how you can reduce your costs. Therefore the aim of Lean and the Toyota Production System is to reduce costs so that the company can make a profit, not to manipulate your selling price to create a profit.

Cutting Costs

Lean is about removing Cost; but it is about removing cost by focusing on what adds value not just trying to identify the wasteful steps in an isolated process.

We have to understand the Value Stream; how do we add value to our process right from raw materials through to the final customer, even the disposal of our product. It is by understanding how that value is added and avoiding the non-value adding steps that we remove waste from our processes. Lean helps us to remove the seven wastes from our processes;

- Transport

- Inventory

- Motion

- Waiting

- Over Processing

- Over Production

- Defects

Those implementations that focus on the removal of the seven wastes from an isolated process within the full value stream tend to make the system less able to cope with change. It is far more effective use techniques such as Value Stream Mapping to understand the whole Value stream from start to finish.

Lean and People

One of the most important aspects of Lean is the involvement of everyone in the organization from the CEO down to the guy that cleans the toilets. Everyone has a voice and everyone is expected to make a contribution within Lean.

While Ford used the ideas of Taylor and Gilbreth to create an efficient production process it very much relied on experts and management defining the production process and the workers following their instructions. Followers of Taylor may say that this was a misinterpretation of his work it was however how it was enforced within Ford and many other companies; the management provide direction and the workers did the work. This often led to resentment from the workers who felt that although wages improved they were being exploited and labor disputes often resulted.

Toyota and other Japanese companies however followed the ideas promoted by Juran, Deming and the other quality Gurus and they began to involve all of their employees in their improvements. From quality circles and kaizen through to Total Productive Maintenance (TPM) and 5S they valued and involved all of their employees. They saw their workforce as their greatest asset and sought to harness the power and creativity of their workers in improving their workplace.

It is often this involvement of the workforce where western companies fall down when implementing lean, while they may say that they value and involve their employees many fail to actually demonstrate it. Unless everyone in the organization is empowered and in fact compelled to participate in Lean it will never be an effective implementation.

Lean is about Exposing and Solving Problems

Another way to look at lean is to look at the way that most of the lean tools and techniques work, they use visual management techniques to make problems obvious; andon boards tell you which machines are not working, daily/hourly achievement boards show you where production is behind,5S layout shows when things are missing or placed incorrectly, Jidoka, and so on. All Lean tools are designed to highlight problems within the system which then have to be solved by the application of the various quality tools and the 5 whys to eliminate the root cause. Continually eliminating problems as they are exposed by the lean system using the power of your workforce teams ensures that you continuously improve every aspect of your business towards perfection as suggested within the 5th lean principle above.

Lean is Not Just For Manufacturing

While Lean has been developed primarily within a manufacturing environment the ideas behind lean are as applicable (if not more so) to service industries and even the various service departments within a manufacturing company. We are focusing on customer satisfaction and what is value as perceived by a customer.

So if value is an invoice that is accurate and delivered within 30 minutes through email then we had better make sure that the service department that provides this service does so. If value is a computer technician that can diagnose and fix 95% of our faults over the phone and internet then that is what we want. If Value is a quick diagnosis followed by rapid effective treatment then that is what we should provide.

Every function of a business has a customer and a purpose (If not why is it there?) What does that customer want and how can you provide them their service when they want it, in an efficient, cost effective way, perfectly every time?

Lean is Not Just Tools

Lean Manufacturing Tools are a means to an end, they are proven methods to achieve a lean state within your business but every tool needs to be adapted and refined for your specific situation. Just implementing individual lean tools on their own will not give you a sustainable improvement in your business, you have to look at the overall philosophy and the principles of lean.

Lean Manufacturing Tools are a means to an end, they are proven methods to achieve a lean state within your business but every tool needs to be adapted and refined for your specific situation. Just implementing individual lean tools on their own will not give you a sustainable improvement in your business, you have to look at the overall philosophy and the principles of lean.

While each lean tool can undoubtedly add value you to your business in its own right, especially tools such as 5S, they are best implemented within a full lean project. Lean tools are not something that can be just read from a book and implemented without any thought, each will require adaptation to fit your company. Without focusing on the main lean principles such as identifying value as perceived by the customer they will add little value to you on their own.

Can a Company Ever Be Lean?

I am sure some off you have heard someone say that they have “done lean”, but is lean something that can actually be achieved? Well Toyota do not believe that they are truly lean, they assess themselves and their suppliers and they think of themselves as only part way on the Lean Journey.

Lean is about Customer Value first, so if what customer’s value over time changes so will the requirements on our business change. Consumer’s expectations are constantly changing and evolving and so must our businesses if we want to succeed. If we stand still someone else will develop something better or faster or they will be able to provide better quality, quicker delivery or a lower cost and then we will lose our customers.

Of course it is this point when most companies start to look to Lean and other philosophies to rescue them from the results of their inaction and complacency. It takes a crisis to get many companies to look at what their customers really want and how they can provide it better, but often when they get to this point it is often too late.

What is Lean Manufacturing?

Womack and Jones define 5 main principles of Lean Manufacturing;

1. Define Value as Perceived by the Customer

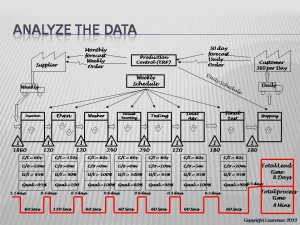

2. Identify the Value Stream

3. Make the Value Stream Flow

4. Flow at the Pull of the Customer

5. Strive for Perfection

These principles form the Backbone of Lean Manufacturing and are achieved through respecting and involving your workforce in every aspect of your business.

Many people define Lean as being about eliminating waste, while in some ways they are right, Lean is more about preventing waste. By implementing the lean principles above you identify those actions that add value and make them flow at the pull of the customer, this prevents the waste from occurring. Lean is not a hunt for waste it is a journey to add value.

Whilst Lean Manufacturing has a huge toolbox of tools and techniques you cannot define Lean Manufacturing from those tools. Lean is more than the sum of all of those tools, applying tools in isolation will not necessarily give you the benefits that you would expect and want to see.

Lean Manufacturing Definition

My own personal definition of Lean Manufacturing is as follows;

“Providing total satisfaction to your customers by pulling value from the value stream when required by your customers using the minimum amount of resources. This is achieved through the involvement and respect of all employees and is a never ending journey towards perfection.”

It is difficult to define Lean in just a few sentences as Lean encompasses so much. Lean is about creating value, it is about customer service, it is about revolution and evolution of your systems and processes, it is a journey towards success.

If you want your company to thrive not just struggle to survive in this global economy then Lean techniques are core.

Lean vs Six Sigma

There is much written about the differences between Lean and Six Sigma and many people ask which should they adopt? Which system will give them the biggest (and fastest) benefits? Lean vs Six sigma is a question that I hear often.

The answer is why chose? The two are not mutually exclusive; you can apply both side by side. Lean in my mind is better at establishing a bigger picture for organizational development and for establishing a firm foundation through things like standard operations and 5S. Six Sigma has superior problem solving tools using DMAIC and various statistical tools.

This is why you will often see companies promoting “Lean Sigma” or “Six Sigma Lean”.

Agile Manufacturing vs Lean

Lean is by definition “fast, flexible, flow” the very things that Agile manufacturing tries to achieve. Agile is an attempt to re-brand Lean Manufacturing because of many organizations failure in the past to focus across the entire value stream when applying lean manufacturing. Too many people in the past have used a lean definition that concentrates purely on waste reduction and have created anorexic processes that fail as soon as customer demand changes.

Agile tries to address this weakness by focusing across the supply chain.

What is Lean Video

Great article, thanks for sharing.

I agree with your comments on Lean vs Six Sigma. By utilising both system you can select the best tools for the task at hand and achieve a better result.

I FULLY CONCUR

I am trying to get a Team Coordinator position and I am learning all about lean manufacturing…this website has LOTS of info!! Thanks!!

I would like to learn more about Lean.

Regards,

Eddie

Great article -providing information in a very simple understandable language-thanks for bringing it- sir provide your valuable knowledge for beginners like me. Thanks once again

I would like to know more about critical factor of lean implementation in manufacturing.

Also would to think you for this web.

Dear Sir

I am very interested with the lean manufacturing principle and I am going to implement in my company which is engaged in soap and detergent.

Would you please send me some of the videos freely for training purpose.

Thanks in advance

Yonas Girmachew

Lean manufacturing concept is good and please provide me 10 tips guidelines to implement in our company to get the results