In their book “The Machine That Changed the World” Womack and Jones define 5 principles of Lean Manufacturing. These Lean Principles define the philosophy of lean.

These principles are;

- Specify Value as perceived by the Customer

- Identify the Value Stream

- Make the Value Flow through the Value Stream.

- Pull the Value from the Value Stream

- Strive for Perfection.

The Principle of Value

You need to define exactly what it is that the Customer wants, not what you think the product is but what is value in their eyes. The customer wants rapidly safely cooked food, not necessarily a microwave oven, the Customer wants access to the internet, not necessarily a desktop computer and so on. It is not about the producer forcing what is most convenient for them onto the consumer.

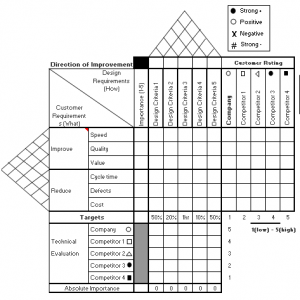

The use of Brainstorming, Quality Function Deployment (QFD) and other ideas can help an organization to define exactly what the customer sees as value.

What is Value?

Value is something that the customer specifically wants and is prepared to pay for. Yet we spend the majority of our time doing something other than adding value. Studies show that we tend to only add value to a product or service for just 5% of our time. The rest of the time we spend in wasteful pursuits; we are waiting, reworking, transporting, moving and a host of other wasteful things that the customer does not consider to be something that they should pay for.

These are the seven wastes of lean and a lot of what we do within a lean manufacturing implementation is to seek out these wastes to eliminate them. However this often going about lean the wrong way. We need to seek out the value adding steps and make those as efficient and free of waste as possible. Just looking for waste we tend to start working on improving processes that are in themselves wasteful and unwanted by the customer. We end up making non-value adding processes more efficient.

The Lean Principle of Value Stream

The value stream is the series of interrelated processes that produce the value; from raw material through to use. Just the steps that add the value, not those steps that add no value. Value adding and non-value adding steps make up every process. Within lean we are looking to remove or minimize those non-value adding steps.

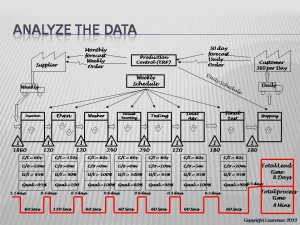

We are looking at the value stream from the point of view of the product (or value), not looking at individual departments or even companies. This can be mapped using tools such as value stream mapping to create current and future state maps of the overall flow.

Think about the actual processes when you define the process stream; not in terms of your companies departments. Many lean implementations end up creating value streams where there are no “departments” as such but a pure flow through the company for the value itself.

The Principle of Making Value Flow

The ideal flow would be “one piece flow”, however this is often not feasible due to machine setups and the need to flow multiple product streams through individual machines or cells. But what we are trying to achieve is the “flow” of products or value from one step to the next, each step being a value adding step. Never delay a value adding step by a non-value adding step, where possible have these done in parallel to the value adding one.

This flow is achieved through a whole host of ideas and tools from Kanban, to small machines, through cell design and so on.

Pull systems a Lean Principle

One of the biggest wastes in any system is that of inventory; inventory hides all of the other problems in your system and causes so many other wastes. Inventory takes up space, it requires stacking, storing and transporting, it eats your capital!

The ideal system is one where the customer makes the order and you manufacture that product only when ordered. This is an ideal situation and many industries do not believe that they can achieve it. But lean is a never ending journey and with evolving technology and customer requirements it is possible to achieve it.

Consider a book; if you go into a book store there are shelves that are stacked high with thousands of books, some which will never be purchased and will either be sent to “bargain clearance outlets” or will be pulped. The reason being that the huge presses that produce these books have to be run for “economic” batch sizes. But with today’s technology people no longer need the printed book, they can download the text to their kindle or laptop and read it on demand. For those that still want the feel of the printed word in their hands many bookstores now have machines which will print and bind your individual book while you wait! Single piece flow at the demand of the customer in an industry that would have laughed at you if you suggested it a few years ago!

Pull production rather than pushing production through a factory using scheduling can be achieved very simply in many cases. By using kanban systems and “supermarkets” it is possible to set up your production so that customer orders can be quickly satisfied when they are made and the parts either manufactured to order from standard components or drawn from a small buffer stock and then replenished in much the same way a super market will refill the shelves as customers buy product. In fact it is a super market that gave the idea for this method of production.

Perfection

If you achieve the first four steps you will have already prevented a huge amount of waste (seven wastes) from appearing within your processes. However; with the help and support of all of your employees you need to strive towards perfection; delivering exactly what the customer wants, when they want it at an acceptable (Minimum) price with zero waste.

Don’t go out and benchmark your competitors and try to match them or beat them by a little; the aim is zero waste and the ability to deliver your customers value.

Involve every employee within your company in implementing lean tools such as Kaizen to drive continuous improvement of each and every aspect of your company. Lean is not just about improving a production cell; it also about improving every other process from order processing to invoicing and customer service.

Lean Thinking

Lean Thinking is applying these principles to your organization, whether it is a manufacturing or a service organization. In fact this is what Womack and Jones emphasize in their follow on book from “the machine that saved the world”;” Lean Thinking“.

In any business you have a customer who has needs; these are the things that he values. You provide this value through a series of interrelated processes that form the value stream, some of your processes and process steps add no or little value, identify those that add value and eliminate or minimize the others.

Make your value flow at the pull of the customer to minimize waste; this is just in time manufacturing (JIT). Then strive for perfection!

This lean thinking can be applied to any business large or small in any industry and can help you to thrive in today’s global economy.

Could you please tell me who the author of this article is and the date of resource creation. I am trying to cite this page.

Thank you.

same here! I want to cite contents from this page as well.

Thank you.

I would like to cite contents from this page as well, please tell me who is the author of this article and the date of resource creation.

Thank you.

Good afternoon

I am currently carrying out my dissertation on the Principles of Lean, in particular how Lean is implemented in a variety of organisations.

If possible, could you please fill out the following questionnaire for my data collection? I am trying to get a wide range of data so that I can find common traits and gaps where Lean has been implemented.

Please don’t hesitate to contact me.

http://kwiksurveys.com/s/TCOEEuSe

Thank you

Kiya Finch

Hi Kiya,

Have completed your survey on Lean for you.

Hello

Have you finished your dissertation ?

I’m working on my dissertation now. It’s about implementing lean production in a furniture small business.

Could you please tell me who the author of this article is and the date of resource creation. I am trying to cite this page.

Thank you.

The author of the post is clearly stated on the right of the page; Tony Earley MSc. Date of publication is June 2011