How much Value do we Add in our processes?

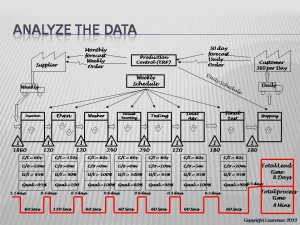

Many studies have shown that we only add value to a product for less than 5% of the time, the rest of the time is wasted! If you were to do a value stream map of your value stream you may be surprised (horrified) at what you would find.

Having done this study myself many times for many companies I have yet to find one that reaches 5%! This is a terrible figure, so imagine if you could improve on this!

But what is waste, we have already defined the seven wastes, muda, mura and muri on other pages within this site but there are still times when we are not sure.

Wasted Time and Money

Within every process there are two elements, those that add value and those that add no value, both take time and cost us money but only one earns us money.

Defining Value and Waste

So how do we define waste or non-value adding processes?

Toyota (Taiichi Ohno) define waste as;

- “anything other than the minimum amount of equipment, materials, parts, and working time absolutely essential to production.”

Another definition of waste is;

- “anything other than the absolute minimum resources of materials, machines, and manpower required to add value to the product.” (Hay 1988)

However both of these are subjective definitions, what is “the absolute minimum”?

A better definition of value adding and non-value adding would be;

- “Only an activity that physically changes the shape or character of a product or assembly can add value.”

- “Any activity that does not change the product or assembly is waste.”

However even this can fall short in some areas, consider the case of conducting a roughing cut, or in over polishing a surface that will never been seen. These change the character and shape of the product but are not necessarily the most efficient use of our time.

Therefore; every activity should be considered to be waste unless it;

- Meets an explicit customer requirement

- Cannot be shown to be performed more economically

Value According to our Customers

The first principle of Lean is to identify value as perceived by our customer. What does our customer really want? What are they willing to pay for? After all if we are doing something that our customer does not explicitly require we are being wasteful.

So what does our customer want? Well this usually can be broken down into three areas; Quality, Cost and Delivery.

Quality

Quality can be more than just “does it function or look as described” it can also be does the product or service have all of the functions and deliver everything that you wanted. Buying a cell phone that has the ability to run all of the latest applications with a fantastic screen and everything else is great, but if it has lousy reception it will not satisfy the customer. Products and services have to deliver exactly what the customer wants, not a compromise that best suits your processes.

Value therefore is having everything that the customer expects and needs. It is also everyone of those attributes working perfectly and reliably.

Delivery

A satisfied customer is one that gets their product or service when they want it, this can be immediate or it may be off in the future. Far too often companies make consumers wait for products when the customer really wants it now. Being able to reduce your lead times can be a real order winner in many industries. Value therefore is giving the customer what they want when they want it.

Cost

No one wants to pay more than they need to for anything. So value is simply doing things in the most economical way without creating waste.

Who is our Customer?

Our Customer is often more than just the company that takes delivery of our products or the consumer that uses them. We also have to consider all of the other “stakeholders” in our business. Society as a whole has an expectation on every business and we as responsible business owners and employees have to consider those needs also.

This can mean ensuring that we don’t pollute our environment or over-consume our resources as well as ensuring that we keep our employees safe. All of these customer requirements are value that we must ensure that we include within our value stream.

We also have to consider our shareholders and business owners who want to see a profit from everything that we do and even the tax man who wants to see auditable records to prove our liabilities.

A value adding process therefore is one that satisfies the needs of one of our many customers or stakeholders, not just the final consumer.

Identifying Value

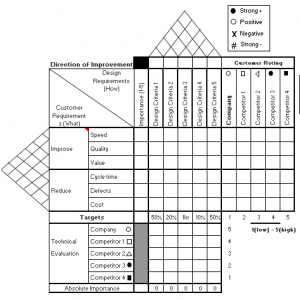

There are a number of different ways to identify value as well as non-value adding steps. We can use Quality Function Deployment to identify value according to the customers and we can use Value Stream Mapping and process mapping to highlight the different steps in our processes and highlight where the value is being added.

Eliminating Non-Value Adding Processes

So when you examine each step of a process you should be asking these questions;

Is this step changing the form or character of the product?

Does this step meet an explicit customer requirement?

If the answer is “yes” then we should then ask ourselves if there is a more economic way to perform this step. This is where the many lean manufacturing tools come into play to help you identify those steps that don’t add value and to eliminate them.

Value Add Video Clip

It was awesome, It helped to build Concept, as It is the New opic added to our Syllabus, and I was studding it for first time. Thanks u so much..

Superb insight of how a VSM can be used