Problems are inevitable, no matter how hard we plan and what precautions we take, they will eventually creep up and bite us. Rushing in and trying to fix the problems quickly, however, rarely seems to truly make these problems go away. Often, they come back time after time. The reason for this is that we fail to use a methodical approach to identify the true root causes of the problems and fail to put in a robust fix that will prevent the problem reoccurring.

A3 problem solving is one easy way to put in place a process that will help you to solve problems permanently as well as making improvements to your processes.

What is A3 Problem Solving

As with many things from Toyota, A3 problem solving attempts to make things as simple and as visual as possible. A3 refers to the paper size used for the reporting and all the process is contained within the confines of this single sheet of 11” by 17” paper. Some suggest that the reason for the single piece of paper is down to the rumored refusal of Taiichi Ohno to read any more than a single page of any report.

There is nothing magical or revolutionary about the process either. It simply follows the Deming’s Plan-Do-Check-Act Cycle or PDCA. It is also very similar to other processes and layouts that other companies have used over the years such as Ford’s 8D process for problem solving.

The effectiveness of the form however lays more in the attitude of the teams implementing the A3 process than the form itself. Problems are opportunities to improve what you are doing and should never simply be seen as just a “problem”.

A3 problem solving sheets are not going to be a magic wand that you can wave over your problems to solve them. Without a dedicated team to follow the process they are unlikely to help you.

The A3 Problem Solving Process

The A3 root cause analysis process is usually broken down into 7 steps, some break it down into 8 or 9, however the total number of steps and what they are called are not important as long as you follow the idea behind them. The steps follow the PDCA process and take you through a logical step by step route to clearly identify:

- What is the problem

- Why we need to fix it

- What is the actual root cause

- How we will contain the problem in the short term

- Plan how we fix the root cause

- Confirmation that the countermeasures fix the issue

- Changes to standardized work to fix the issue permanently

- Share any changes within the company

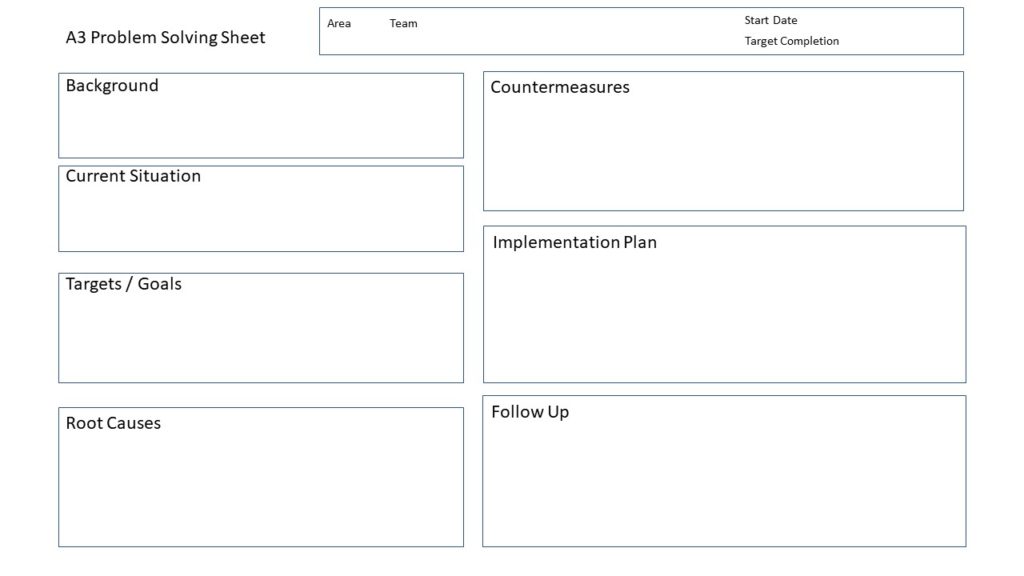

Often these steps are broken down under the following headings on the A3 worksheet:

- Background

- Current Situation

- Targets or Goals

- Root Cause Analysis

- Countermeasures

- Implementation Plan

- Follow Up

This is what should be considered and detailed within each section:

Background

- What is the actual issue that you are looking to correct?

- How does it impact the business objectives? Why do we need to fix it?

Current Situation

It is always best to take your team to where the problem is occurring to see the problem firsthand. Talking about something in a remote location is never going to be as effective as actually observing at the Gemba (Workplace).

The team should carefully detail the problem. This should cover all relevant information such as how often something happens, when, where, etc. Depending on the complexity of the issue it may be necessary to collect data in the form of graphs and control charts or to conduct process mapping exercises to understand what is happening.

Targets / Goals

What does the team see as the ideal solution to the problem? What are we going to achieve? Your objectives should be clearly stated, and a time frame agreed so that all can agree on what you hope to do through your team.

Root Cause Analysis

There are of course many ways that you can arrive at the root cause of your problems depending on the complexity of the problem that you face. The right quality improvement tools should be selected and used from Pareto charts to fishbone diagrams or the 5 whys.

Ensure that your A3 root cause analysis comes up with agreed reasons for your problems. Remember, that there are often multiple causes that may need to be fixed.

Countermeasures

Once you have your root cause(s) identified you can get to work to brainstorm the changes that you need to make to fix the problems. Remember that all fixes should aim to achieve the goals that you have identified earlier in the process.

Action Plan

This is your plan of action to fix the problem that you have identified. This plan should be detailed and include what is to be done, who is responsible, and of course when it will be done by. You should also consider the expected outcome from each action so that you will have a clear idea of whether the action has had any effect on your issue.

Once the plan has been detailed it should be implemented effectively by the team.

Follow Up

Too often teams will stop at the plan implementation stage. They make the changes that they have suggested and then fail to check if those actions have been effective. You must verify the effectiveness of your actions to confirm that they have fixed the root causes that you have identified. Otherwise the problems could easily return.

If the changes have not managed to fix the problem, then the process needs to be revisited. The team needs to work through the cycle once again to see what they have missed and to make alternative plans to fix the problems.

Changes should be made permanent if they are found to be effective through changes to standardized work and other procedural documentation.

Teams should also share what they have learned and implemented within the company. Often there is the opportunity to mirror the changes made to prevent issues occurring in other parts of your business.

Why Use A3 Reporting

The A3 reporting format does not have to limited to simply problem solving. Toyota use it for a number of things such as status reports, improvement suggestions and proposals. Other companies have developed similar reports for things such as coaching. Your imagination and business needs are your only limitation.

The A3 lean process is highly flexible and provides you with a highly visible way to communicate everything from your problem solving to continuous improvement initiatives. Used well with trained and dedicated teams it can really make a huge difference to your company.