“Send me a video of your process and I will help make it more efficient”

One of the most common areas that companies are looking for when looking for any form of lean support is to improve their process efficiency. They want to be able to produce more at a reduced cost whilst often improving quality.

Asking a Lean Consultant to provide support in this area can be an expensive proposition and many Lean Consulting Companies will charge you thousands of dollars every day for their help. While this money is often well spent and you will reap the benefits, not every company can afford this initial outlay, especially smaller businesses.

This is why you may want to consider the benefits of our online coaching. We can offer you all of the help that you may receive from these on site consultants but at a fraction of the cost. Many of these consultants feel that they need to validate their high costs by making what they do seem far more complicated than it really is. We however will get right down to basics and provide you with the skills and understanding that you need to make some real changes quickly and effectively; without needing a degree in Japanese.

How Does Our Online Consulting Work?

We want you to be able to use our coaching to understand how you should go about improving a process and then to be able to use that understanding and apply it by yourself on other areas within your business. We will not overly complicate things and make them seem more difficult than they really are.

Our lean consultant will work with you through email and video chat as required to provide you with the specific help and support that you need.

What Process Improvement Consulting Help Can We Provide You?

Through us there are two main approaches that you can access, although if another approach would suit you better then we are happy to discuss it with you:

Video Based Process Improvement

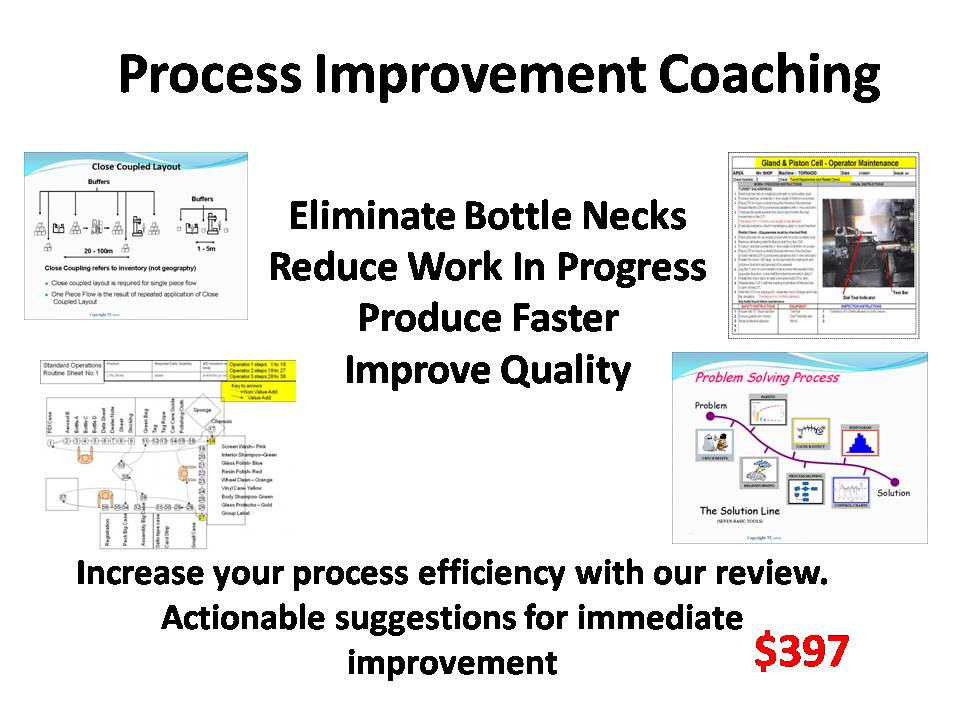

Process Improvement Coaching

We provide this service based on a week-long review of the process that you wish to improve.

- We will ask you to provide us with detailed instructions for the process in question as well as a video of the process. The video can be up to around 45 minutes in length and should give a detailed view of what is actually being done.

- We will review the video and instructions in detail. We use video chat and email to request any additional information regarding what is being done.

- We will then provide you with a detailed analysis of your process identifying the areas that are wasteful and can be eliminated or improved. We will also provide you with our recommendations for the changes that should be made.

The cost of this review is just $397; ORDER

Process Improvement Training and Coaching

Effective One on One Lean Coaching

We offer you 4 weeks (20 days) of support to review your process and to improve it:

- Identifying the process that will be improved

- Identifying and collecting the measures for that process

- Providing relevant training materials such as 7 wastes of lean presentation

- Planning the process for making your improvements

- Walking you through the improvement process

- Review of all of the process steps with suggestions for making improvement

- Problem solving help

- Help with reviewing process instructions to maintain all improvements

Communication is through:

- Daily emails; short video clips, photographs, etc. are encouraged. Response is usually within 24 hours of receiving your email.

- Video chatting; 2 calls per week of around 30 minutes duration.

By using our coaching program you will learn all of the skills and techniques that you need to know to be able to make similar improvements to other processes. The cost of this support is just $797: ORDER

If you feel that you need your coaching delivered in a different manner or would like support in a different area of your business fell free to contact us here today for a no obligation quotation: ORDER